Welcome to Abrasive Grit Manufacturer in India

-

Nature of Business

Abrasive Grit Manufacturer -

Total Number of Employees

26 to 50 People -

Year of Establishment

2000 -

Legal Status of Firm

Limited Company (Ltd./Pvt.Ltd.) -

Annual Turnover

Rs. 2 - 5 Crore

Media Used for Abrasive Grit Blasting

- Aluminum oxide manufacturer: A standard blasting media used for grinding, polishing, surface cleaning, and surface coating. It is a tough, wear-resistant material that's chemically inert and stable at high temperatures. Additionally, aluminum oxide manufacturer is the high purity grades (i.e. aluminum oxide grit, black aluminum oxide, white aluminum) exhibit excellent electrical insulation (dielectric characteristics) and thermal conductivity.

- White aluminum oxide manufacturer: A sharp, reusable and durable abrasive that cleans and penetrates metal; technicians often use it to prepare a metal surface for painting.

- Glass beads manufacturer: Reusable glass media that’s lead- and silica-free to clean and polish metal without causing dimensional changes.

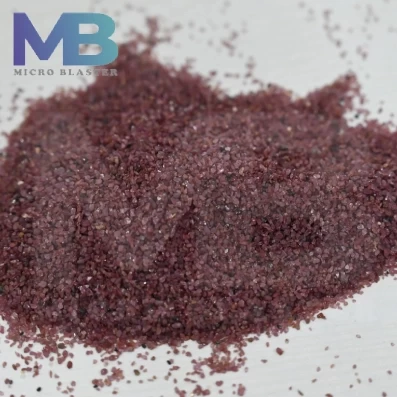

- Garnet Sand 80 Mesh Manufacturer: Garnet Sand is free of metallic iron, making it suitable for all areas of surface preparation including stainless steel, anti-magnetic steel, and every one special alloys and has several benefits, garnet sand manufacturer include the following: garnet sand 80 mesh, garnet sand 40/60 mesh, garnet sand 30/60 mesh, garnet sand 20/60 mesh, garnet 10/30 mesh, garnet 10/20 mesh.

- Steel Shot Manufacturer: It is the most common material used for shot peening. It can are available in a spread of sizes and harnesses. Steel shot manufacturer is classified by the dimensions of the opening during a mesh that retains 80-85% of an attempt. Most common steel shot we have 12 ga steel shot, 28 ga steel shot, 10 ga steel shot, 410 steel shot, 3 inch steel shot.

- Cut Wire Shot Manufacturer: Cut wire shot stops ferrous contamination when blasting or peening stainless steel, titanium, aluminum, or other non-ferrous work purposes. The standard cut wire shot we supply are steel cut wire shot supplier, aluminum cut wire shot supplier, copper cut wire shot supplier, zinc cut wire shot supplier, carbon cut wire shot supplier.

- Crushed glass grit manufacturer: An abrasive made from recycled glass bottles that are used to remove coatings from materials like coal tar, epoxy, paint, and vinyl.

- Acrylic manufacturer: A gentle abrasive used to strip sensitive surfaces.

- Corncob grit manufacturer: A reusable, biodegradable, organic media made from corncobs to clean and remove surface contaminants.

- Pumice manufacturer: An abrasive made from lightweight volcanic rocks that are ideal for less aggressive operations.

- Walnut shells manufacturer: Blasting media made from walnut shells that clean and polish a surface without marring, scratching, or etching it.

- Silicon carbide grit manufacturer: The hardest blasting media available; used for etching stones and engraving glass.

- Steel grit manufacturer: Steel Grit is angular in appearance, very hard, and is considered non-hazardous and contaminant free as received. During use of steel grit manufacturer, it produces no free silica or associated respiratory and environmental hazards. Used when aggressive cleaning is needed on steel or foundry metals; also used for metal. Common steel grit we have steel grit g40, steel grit g25, stainless steel grit.

The choice of the abrasive to be used and the type of equipment required to do the job depends essentially on the nature of the surface involved (including its pre-cleaned surface condition which may include being covered by paint, rust, etc.), the type of treatment desired (cleaning, deburring, etc.) and related concerns. Abrasive blast cleaning usually is considered to be an economical method. It is faster than competitive processes of pickling, electrochemical cleaning, or hand finishing, and thus reduces man-hours required. In addition, equipment investment is not essentially influenced by model changes, operational systems, or personnel turnover; training of operators takes place in the least amount of time, and in many cases, the abrasive media, or substantial portions of them, maybe recycled for further use.

Abrasive Grit Manufacturer Qualities

- Low Dust.

- High Productivity.

- Low Consumption.

- Superior Surface Quality

- Recyclability.

Benefits of Abrasive Grit Blasting for Surface Coating Preparation

Abrasive media manufacturer is commonly economical and many types are reusable. Blasting offers additional economic benefits because it efficiently cleans surfaces better and faster than usual methods. It’s also effective at removing rust on metal surfaces. Abrasive blasting prepares surfaces for coating applications efficiently. During the process, it’s important to keep temperatures and relative humidity levels low using temporary climate control solutions to reduce excess moisture that could hinder the protective coating’s application and drying. Temperature and humidity control is particularly vital when preparing metal surfaces, as the bare metal’s appearance to the environment makes it susceptible to oxidation. Abrasive Grit is a leader in temporary climate control solutions. Whether you’re building a ship or cleaning mechanical elements in a factory, Abrasive Grit will help create an environment that supports worker health and safety, increased productivity, and improved coating performance.

Abrasive Grit Manufacturer in India

Our company is manufacturing a good range of abrasive grit such as- Copper Slag, Aluminum Oxide, Steel Grit, Garnet Sand, garnet sand 80 mesh, Glass Beads, Dust Collector Unit, Sand Blasting Cabinet, Industrial Blowers, Blast Room, Sand Blasting Machine, etc, and cut wire shot supplier and exporter of pneumatically operated & wheel operated blasting machine which are at par fulfilling international quality standards. Except for standardized models, it manufactures custom-built machines as per consumer requirements. The products are thoroughly tested by the quality department & rigorous development is achieved by a professional design team in bringing new concepts. The company offers Cost-Effective, Genuine, and Unmatched Spares for all kind of Sand Blasting Machine. We also supply superior quality safety wears and we are the leading suppliers and exporters of premium quality Abrasives media.

Abrasive Grit Strengths

Backed by huge industry experience and business policies, we have acquired a preeminent position in the market. Our clients have appreciated our efforts and showed their support by placing repetitive order of products. Following factors helped us make a mark in the industry:

- Ethical Business Practices.

- Quality Products.

- Precision Work.

- Competitive Prices.

- Timely Delivery.

BLOGS

See our latest blogs on minerals export,metallic shot, metal grits,industrial steel abrasives media,and steel shots in India.